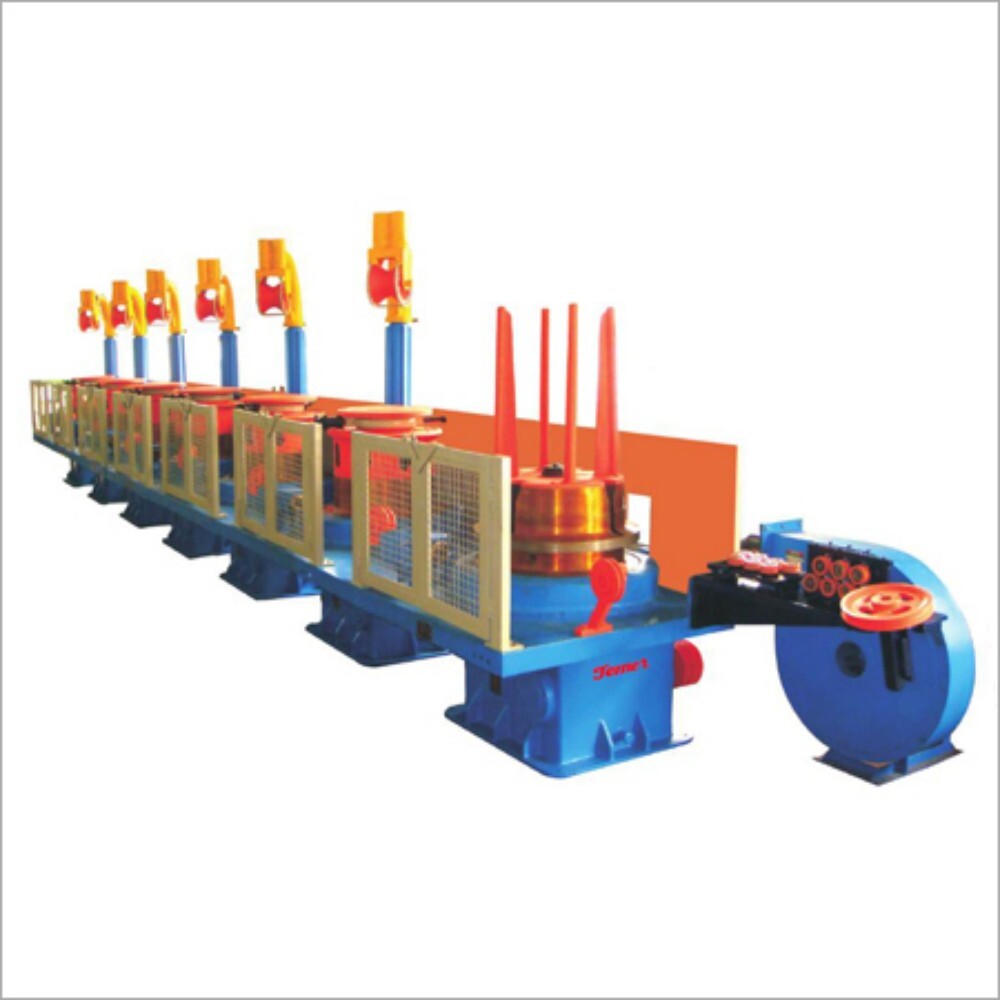

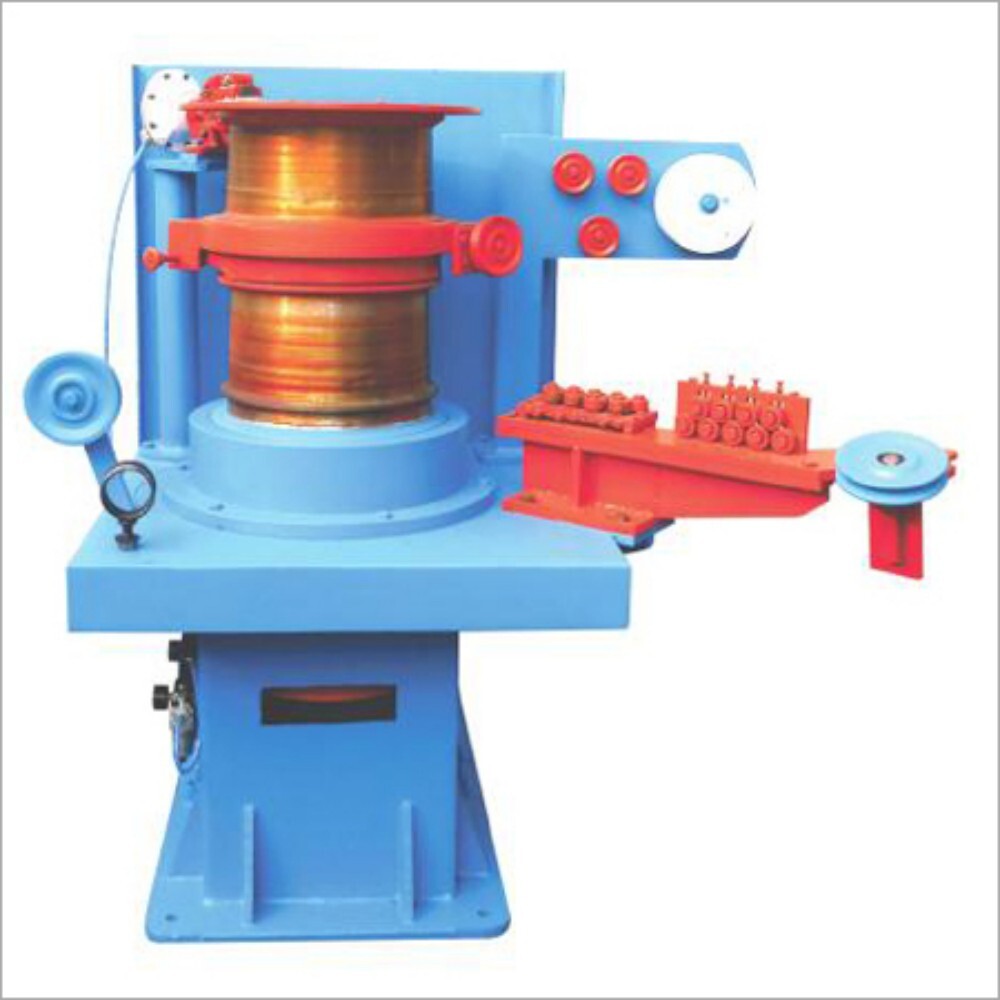

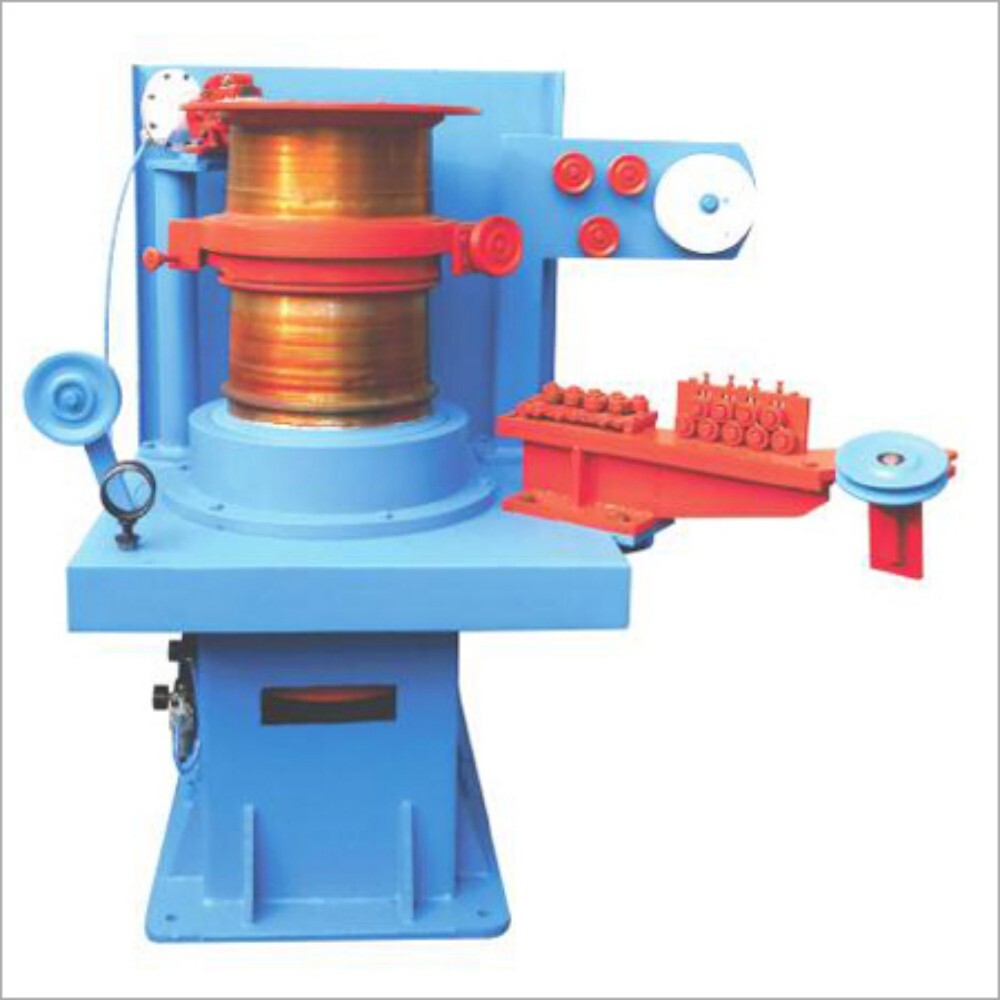

BB Block Machine

BB Block Machine Specification

- Max De-coiler Weight

- 1000 Kg

- Production Capacity

- 3200 Kg/Day

- Product Type

- BB Block Machine

- Application

- Wire Manufacturing

- Inlet Diameter

- 8 mm

- Drawing Passage

- Single

- Wire Material

- Copper, Aluminum

- Power

- 80 kW

- Function

- Wire Drawing and Block Formation

- Drawing Material

- Mild Steel

- Voltage

- 415 V

- Manufacturing Year

- 2024

- Condition

- New

- Production Speed

- 240 m/min

- Cooling Method

- Water Cooled

- Block Diameter

- 560 mm

- Control System

- PLC Automated

- Lubrication

- Automatic Lubrication System

- Operating Temperature

- 0-40C

- Frame Structure

- Robust Welded Construction

- Roller Material

- Alloy Steel

- Safety Features

- Emergency Stop, Overload Protection

- Noise Level

- 80 dB

- Frequency

- 50 Hz

- Paint Finish

- Powder Coated

BB Block Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 24 Pieces Per Month

- Delivery Time

- 4 Week

About BB Block Machine

Our company is a prominent supplier and manufacturer of BB Block. It is fabricated at our state of the art manufacturing unit, which is loaded with latest machines and cutting edge tools. Owing to this ultra modern facility and dedicated technocrats, we can create a perfect BB Block as per international standards and also meet bulk requirements of the customers within promised duration. The offered device is widely appreciated due to its sturdy construction, corrosion resistance, high efficiency and compact design.

BB Block

|

Type |

17DHA |

18DHA |

|

Input Wire |

|

|

|

Output Wire |

|

|

|

Maximum Line Speed |

|

|

|

Maximum Number Of Dies |

|

|

|

Mechanical elongation |

|

|

|

Drawing Capstan |

|

|

|

Take-up reel |

|

|

|

Final capstan |

|

|

|

Drawing/take-up motor |

|

|

|

Power supply |

|

|

|

Brake |

|

|

|

Volume of lubricant |

|

|

|

Lubrication of wire drawing |

|

|

|

Dimensions (L x W x H) |

|

|

|

Weight |

|

|

Advanced Automation for Enhanced Efficiency

Equipped with a sophisticated PLC control system, the BB Block Machine automates the wire drawing and block formation process. The seamless integration of automatic lubrication and water cooling optimizes performance, minimizing downtime, and enhancing workplace safety. Its frequency of 50 Hz and robust structure deliver both reliability and consistent production output.

Superior Build Quality and Durability

Manufactured with a robust welded frame and alloy steel rollers, the machine provides longevity in demanding environments. The powder-coated finish offers excellent resistance against corrosion, while the automatic lubrication system reduces maintenance efforts, ensuring that each component operates smoothly throughout its service life.

High Production Capacity and Versatile Application

Ideal for wire manufacturing, the BB Block Machine processes mild steel drawing material to produce copper and aluminum wires. Capable of handling up to 3200 Kg per day and operating at speeds reaching 240 m/min, it meets the needs of manufacturers, suppliers, and traders seeking efficiency and versatility for their operations.

FAQs of BB Block Machine:

Q: How does the PLC automated control system enhance the operation of the BB Block Machine?

A: The PLC automated control system manages the entire wire drawing and block formation process, enabling precise adjustments, real-time monitoring, and seamless automation. This results in consistent production quality, reduced manual intervention, and increased operational safety.Q: What is the cooling method used in the BB Block Machine, and why is it important?

A: The machine uses a water-cooled system that dissipates heat effectively during production, maintaining optimal temperatures for safe operation and prolonging the service life of its components.Q: When should the BB Block Machine be maintained and how does the automatic lubrication system help?

A: Scheduled maintenance should follow the manufacturers guidelines; however, the integrated automatic lubrication system continuously supplies oil to critical parts, significantly reducing wear and extending intervals between manual servicing.Q: Where can the BB Block Machine be installed and what are its space requirements?

A: It is suitable for production facilities or workshops involved in wire manufacturing, especially in industrial settings across India. The robust welded frame allows flexible installation, but sufficient space is needed for safe operation and maintenance access.Q: What benefits does the emergency stop and overload protection provide?

A: These safety features enable immediate shutdown in case of emergencies and protect the machine against operational overload, helping to prevent accidents and minimize equipment damage during unforeseen events.Q: How does the BB Block Machine cater to different wire materials and diameters?

A: Designed for versatility, the machine supports drawing of copper and aluminum wires from mild steel material, handling inlet diameters up to 8 mm, making it suitable for diverse production needs.Q: What is the typical production capacity and speed of this machine?

A: The BB Block Machine achieves a production capacity of up to 3200 Kg per day and operates at speeds of up to 240 meters per minute, providing high efficiency for large-scale wire manufacturing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Block Wire Drawing Machine Category

Cover Wire Drawing Machine

Price Range 200000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dry Block Wire Drawing Machine

Price Range 200000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dry Wire Drawing Machine

Price Range 2000000.00 - 5000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

|

TOMER ENGINEERING WORKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry