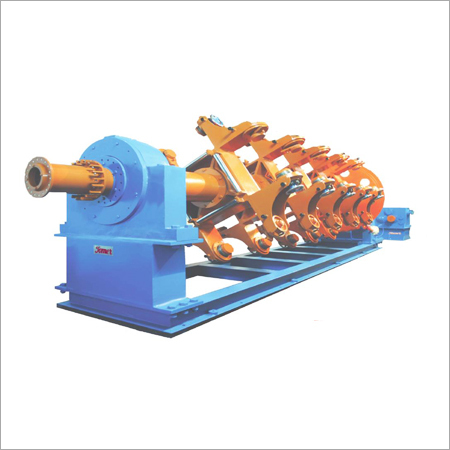

Wire Stranding Machine

Wire Stranding Machine Specification

- Power

- 15 kW

- Drawing Material

- Copper, Aluminium

- Function

- Wire Stranding

- Product Type

- Wire Stranding Machine

- Production Capacity

- 500 kg/h

- Wire Material

- Copper/Aluminum

- Application

- Wire and Cable Manufacturing

- Condition

- New

- Manufacturing Year

- 2024

- Drawing Passage

- 7-61 (depending on model)

- Inlet Diameter

- up to 1.2 mm

- Production Speed

- Max 1500 rpm

- Max De-coiler Weight

- 1500 kg

- Voltage

- 380 V

Wire Stranding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 24 Pieces Per Month

- Delivery Time

- 4 Week

About Wire Stranding Machine

We are a widely acclaimed manufacturer and supplier of Wire Stranding Machine. It is made up of premium grade materials that are procured from the most reliable vendors of the domain. The offered machine is manufactured by using modern technology and reliable methods in synchronization with industry defined quality parameters. Our Wire Stranding Machine is tested on set quality standards that ensure its optimum functionality and longer service life. Moreover, our machine is widely appreciate for its sturdy construction, easy operation and minimum maintenance.

Technical Specification:-

|

Type |

17DHA |

18DHA |

|

Input Wire |

|

|

|

Output Wire |

|

|

|

Maximum Line Speed |

|

|

|

Maximum Number Of Dies |

|

|

|

Mechanical elongation |

|

|

|

Drawing Capstan |

|

|

|

Take-up reel |

|

|

|

Final capstan |

|

|

|

Drawing/take-up motor |

|

|

|

Power supply |

|

|

|

Brake |

|

|

|

Volume of lubricant |

|

|

|

Lubrication of wire drawing |

|

|

|

Dimensions (L x W x H) |

|

|

|

Weight |

|

|

Advanced Touch Control for Precision

Featuring a user-friendly PLC touch screen, this wire stranding machine offers precise control over operational parameters. Operators can easily adjust settings such as stranding pitch, cage diameter, and tension. The intuitive interface improves productivity, accuracy, and reduces the learning curve, ensuring efficient setup and operation on the manufacturing floor.

Robust Construction and Safety

Built for durability, the machine employs a rigid or planetary rotor suitable for heavy-duty use in industrial environments. Full safety enclosures with interlocks safeguard operators while maintaining productivity. The automatic oil lubrication system reduces maintenance downtime, delivering continuous operation without manual intervention.

Versatile and Efficient Production

Capable of processing copper and aluminum wires with a production capacity up to 500 kg/h, the machine supports both bobbin and drum pay-off types. Its adjustable tension system ensures consistent results across various wire types and sizes. With models supporting 7 to 61 drawing passages, it addresses a broad range of wire stranding applications.

FAQs of Wire Stranding Machine:

Q: How does the PLC touch screen enhance the operation of the wire stranding machine?

A: The PLC touch screen allows operators to manage and fine-tune machine parameters in real time, such as stranding pitch, speed, and tension. This digital interface enhances usability, reduces setup time, and minimizes errors, providing reliable and precise control for efficient wire and cable production.Q: What materials can be processed with this wire stranding machine?

A: This machine is designed to strand both copper and aluminum wires with an inlet diameter of up to 1.2 mm, making it suitable for a wide range of applications in the wire and cable manufacturing industry.Q: When is it advisable to use the automatic oil lubrication system?

A: The automatic oil lubrication system operates continuously during machine use, ensuring all critical moving parts receive consistent lubrication. This minimizes wear, extends component life, and reduces the frequency of scheduled manual maintenance sessions.Q: Where can this machine typically be installed and used?

A: This wire stranding machine is ideal for installation in wire and cable manufacturing plants, particularly those involved in large-scale copper or aluminum wire production. It is suitable for use by manufacturers, suppliers, and traders throughout India and similar industrial settings.Q: What is the process flow for stranding wire using this equipment?

A: Wire is fed from bobbin or drum pay-off units into the stranding cage, where it is twisted at the desired pitch and tension. The machines PLC control manages parameters, while the automatic lubrication and adjustable tension ensure consistent, high-quality output. The stranded wire is wound onto a take-up reel for further processing.Q: How does the safety enclosure with interlocks benefit operators?

A: The full safety enclosure, equipped with interlocks, prevents accidental access to the moving or energized parts of the machine. It helps avoid workplace injuries, ensures compliance with safety standards, and allows for safe, unattended operation during production cycles.Q: What are the main advantages of using this wire stranding machine for production?

A: Key benefits include high production capacity up to 500 kg/h, flexible processing of copper and aluminum, efficient power transmission with inverter-driven AC motors, precise adjustable tension, an automatic lubrication system, and advanced safety features, all contributing to reduced downtime and consistent product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stranding Machine Category

Stranding Machine

Price Range 1.00 - 10.00 INR / Number

Minimum Order Quantity : 1 Number

Production Speed : Highspeed Sets/Hour

Max De-coiler Weight : 500 kg

Voltage : 380V/50Hz Volt (v)

Manufacturing Year : 2023 Years

Rigid Stranding Machine

Price Range 2000000.00 - 5000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

|

TOMER ENGINEERING WORKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry