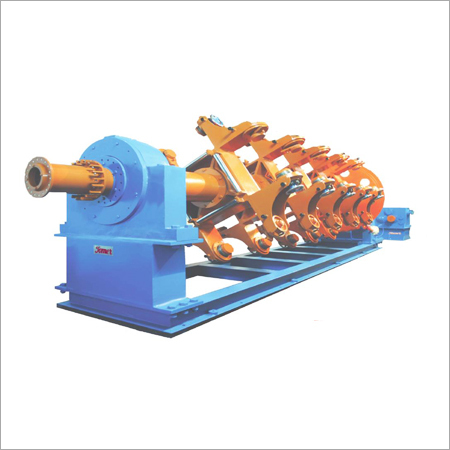

Rigid Stranding Machine

MOQ : 1 Piece

Rigid Stranding Machine Specification

- Product Type

- Rigid Stranding Machine

- Power

- 30-75 kW (Depending on model)

- Drawing Passage

- Up to 37 Passes

- Production Capacity

- Up to 6 Tons / Day

- Max De-coiler Weight

- Up to 3000 kg

- Condition

- New

- Function

- Stranding and Compaction

- Manufacturing Year

- 2024

- Inlet Diameter

- 1.5 mm - 5.0 mm

- Production Speed

- Max 120 m/min

- Wire Material

- Copper, Aluminium

- Application

- Wire and Cable Manufacturing

- Drawing Material

- Copper, Aluminium

- Voltage

- 380-440V, 3 Phase, 50/60 Hz

- Core Loading

- Manual / Automatic

- Bobbin Size

- 500mm - 800mm

- Noise Level

- Below 85 dB

- Cage Rotation Speed

- Up to 220 RPM

- Lubrication System

- Automatic Oil Circulation

- Stranded Wire Outer Diameter

- Up to 54 mm

- Control System

- PLC with HMI

- Drive Type

- AC Frequency Drive

- Take-up Reel Size

- 630mm - 1600mm

- Safety Features

- Emergency Stop, Safety Cover

Rigid Stranding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 24 Pieces Per Month

- Delivery Time

- 4 Week

About Rigid Stranding Machine

Our organization is a celebrated supplier and manufacturer of Rigid Stranding Machine. It is used for the protective covering of power cables, aluminum cables, copper cables etc. Our deft professionals manufacture this machine by using cutting edge procedures and graded materials in synchronization with domestic as well as international standards. The offered Rigid Stranding Machine find its application in mechanical, engineering and cable & wire industries. It is highly demanded due to low power consumption, easy installation, efficient performance and longer service life.

Advanced Stranding and Compaction Efficiency

Engineered for high productivity, the rigid stranding machine achieves production speeds of up to 120 meters per minute and can strand wire with outer diameters up to 54mm. Designed for intense operation with drawing passages up to 37, this equipment is ideal for cable production facilities requiring efficient, high-volume output with minimum downtime.

Sophisticated Control and Safety Systems

Featuring a state-of-the-art PLC with HMI, the machine offers intuitive, centralized control for seamless operation and precision monitoring. Advanced safety measuressuch as emergency stop and protective coversensure operator safety. An automatic oil circulation system provides consistent lubrication, enhancing long-term durability and operational reliability.

FAQs of Rigid Stranding Machine:

Q: How does the rigid stranding machine improve wire and cable production efficiency?

A: Designed for large-volume manufacturing, the rigid stranding machine delivers speeds up to 120 meters per minute and a maximum daily output of 6 tons. This efficiency is achieved through reliable cage rotation (up to 220 RPM), automatic lubrication, and PLC-controlled processes, reducing operational interruptions and manual intervention.Q: What types of wire materials can be processed with this machine?

A: The machine is engineered for copper and aluminium wire processing. Both stranding and compaction functions are supported, accommodating wire inlet diameters from 1.5 mm to 5.0 mm and stranded wire outer diameters up to 54 mm, making it suitable for diverse cable manufacturing needs.Q: When should the core be loaded manually versus automatically?

A: Manual loading may be suitable for short runs, frequent changeovers, or delicate handling requirements. Automatic core loading is preferred for continuous, high-capacity production environments to minimize labor, ensure consistent feeding, and enhance overall throughput.Q: Where is this machine most commonly used?

A: This rigid stranding machine is primarily utilized in wire and cable manufacturing plants throughout India, catering to manufacturers, suppliers, and traders who produce high-quality copper and aluminium cables for various industrial and commercial applications.Q: What is the process for setting up and operating the machine?

A: Setup involves configuring the bobbin (500-800mm), ensuring correct electrical connections (380-440V, 3-phase), and selecting the desired control parameters via the HMI panel. After loading the core (manually or automatically), operators can initiate the stranding process while automatic systems manage lubrication and safety protocols.Q: What are the main benefits of using this machine for cable manufacturing?

A: Operators benefit from increased productivity, reduced downtime due to automated lubrication, enhanced safety features, and user-friendly controls. Its capacity to handle heavy-duty workloadsup to 3000kg de-coiler weight and 37 drawing passagesmakes it an efficient solution for high-demand production lines.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stranding Machine Category

Wire Stranding Machine

Price Range 2000000.00 - 5000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Function : Wire Stranding

Max De-coiler Weight : 1500 kg

Condition : New

Production Capacity : 500 kg/h

Stranding Machine

Price Range 1.00 - 10.00 INR / Number

Minimum Order Quantity : 1 Number

Function : To twist and strand wires or cables

Max De-coiler Weight : 500 kg

Condition : New

Production Capacity : 500 m/hour Pcs/hr

|

TOMER ENGINEERING WORKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry