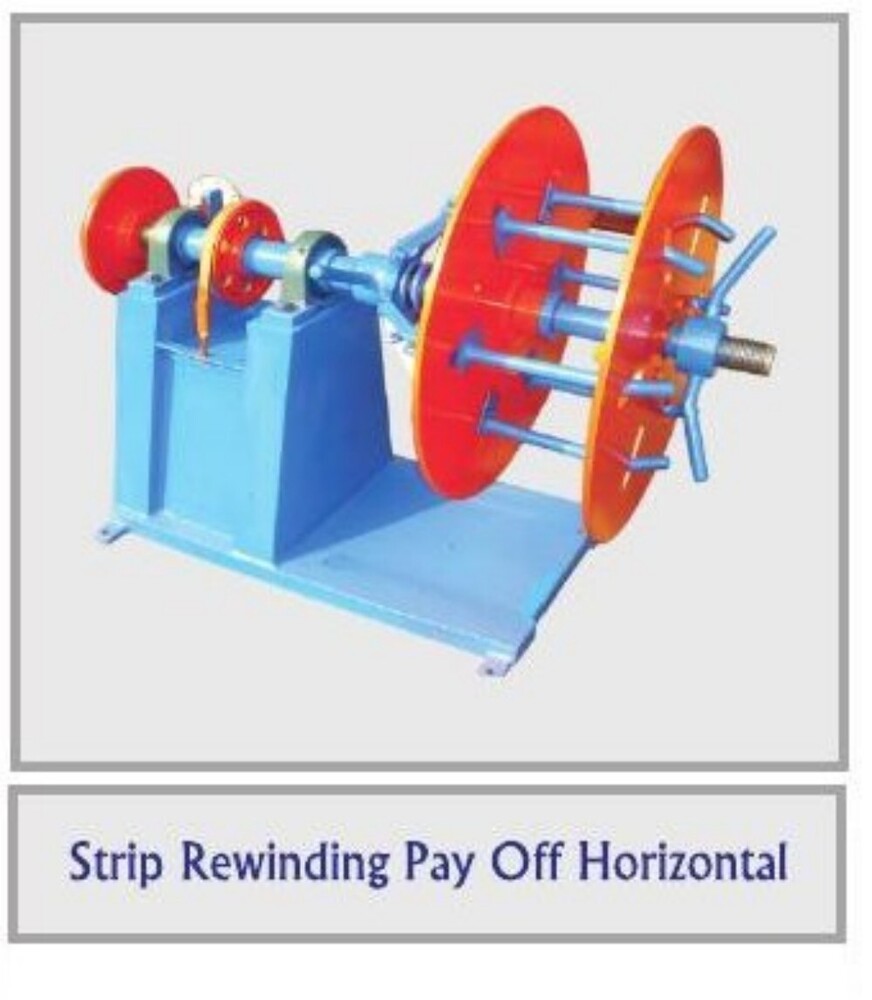

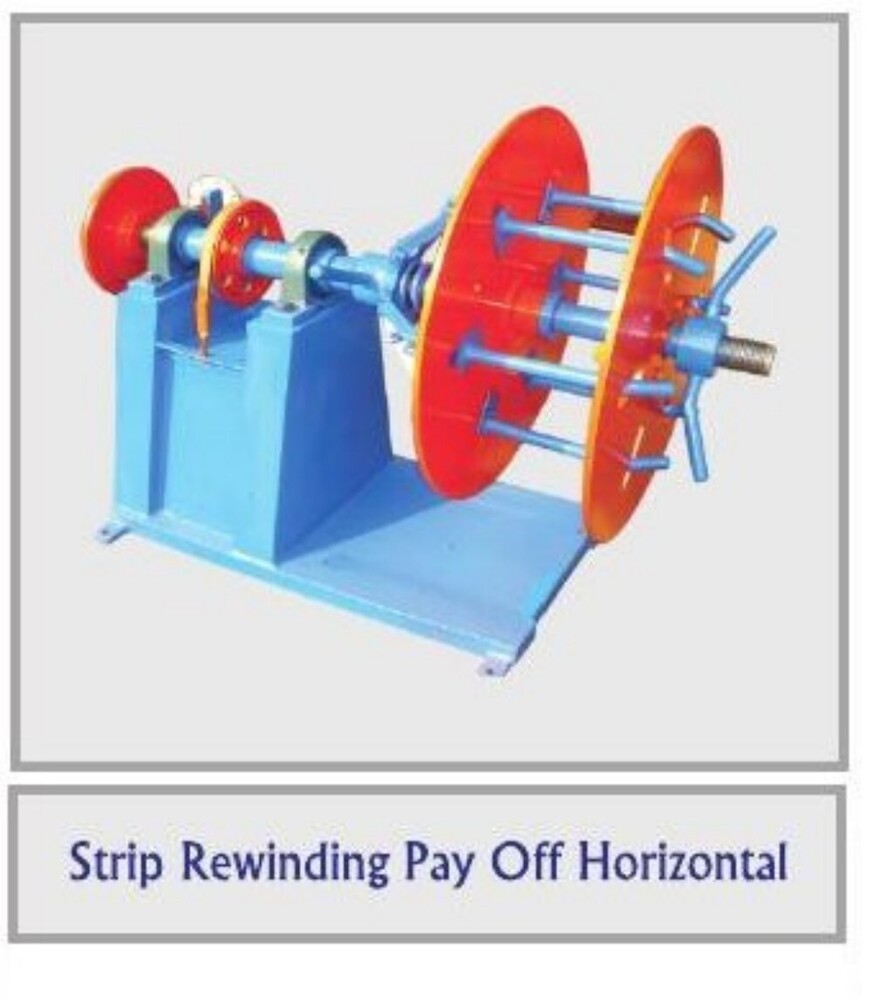

Strip Rewinding Pay Off

Strip Rewinding Pay Off Specification

- Application

- Strip Rewinding, Decoiling, and Wire Pay Off

- Production Speed

- up to 100 m/min

- Function

- To unwind and rewind strips for further processing

- Inlet Diameter

- 300 mm

- Max De-coiler Weight

- 2000 kg

- Production Capacity

- 1500 kg/hr

- Manufacturing Year

- 2024

- Drawing Material

- Metal Strips

- Power

- 5 HP

- Condition

- New

- Product Type

- Strip Rewinding Pay Off

- Drawing Passage

- Single

- Voltage

- 415 V

- Wire Material

- Copper, Aluminum, Steel

- Safety Feature

- Emergency Stop Button

- Surface Finish

- Powder Coated

- Decoiling Direction

- Left/Right

- Drive Type

- Electric Motor

- Strip Width Range

- 30 mm to 400 mm

- Rewinding Tension

- Adjustable

- Operation

- Automatic/Semi-Automatic

- No. of Spools Supported

- 1

- Frame Material

- Mild Steel

- Control Panel

- PLC Controlled

Strip Rewinding Pay Off Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 24 Pieces Per Month

- Delivery Time

- 4 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Strip Rewinding Pay Off

The Strip Rewinding Pay Off is an essential piece of equipment for efficient wire and strip handling in industrial operations. Designed to ensure smooth and reliable feeding of strips or coils, this machine minimizes the risk of tangling and ensures consistent tension control throughout the process. Built with high quality materials, it provides exceptional durability and long lasting performance. The easy to operate system allows for quick adjustments and setup, making it ideal for various manufacturing and processing applications.

Whether you are working with metal, wire, or other materials, the Strip Rewinding Pay Off ensures precise and uninterrupted workflow. It is the perfect solution for optimizing productivity and maintaining high quality standards in your operations.

Precision and Versatility in Strip Handling

Engineered for strip rewinding and decoiling applications, this machine excels in handling diverse metal materials. Its adjustable tension mechanism ensures each spoolcopper, steel, or aluminumis processed uniformly, preventing material wastage. Suitable for a variety of industries, the equipment meets demanding production rates up to 1500 kg/hr while offering left or right decoiling options for flexible setup.

User-Centric Automated Operation

Seamlessly switch between automatic and semi-automatic modes, granting operators control over production needs. Integrated PLC control panels simplify monitoring, adjusting parameters like rewinding speed and tension swiftly. The robust emergency stop mechanism and powder-coated mild steel frame amplify operator safety while enhancing the longevity of the machine in rugged industrial environments.

FAQs of Strip Rewinding Pay Off:

Q: How does the Strip Rewinding Pay Off machine operate?

A: The machine utilizes a 5 HP electric motor and PLC-controlled panel to automate or semi-automate the process of unwinding and rewinding metal strips for further processing. Operators can adjust rewinding tension, set decoiling direction, and manage production through an intuitive control system.Q: What materials and strip dimensions can this machine handle?

A: This unit supports copper, aluminum, and steel strips with a width range between 30 mm and 400 mm, and an inlet diameter of 300 mm. It can manage spools weighing up to 2000 kg, providing flexibility for various manufacturing requirements.Q: When is the Strip Rewinding Pay Off most beneficial in the manufacturing process?

A: It is particularly advantageous when precise control over rewinding or decoiling tension is needed, such as preparing metal strips for subsequent processing steps in wire or strip manufacturing industries. Its speed and capacity optimize throughput during high-demand operations.Q: Where can this rewinding machine be installed?

A: Designed for industrial setups in India, the machine is suited for manufacturing plants, wire processing units, and metal strip product facilities that require efficient strip rewinding or decoiling operations.Q: What are the safety features integrated into the equipment?

A: The machine is built with a highly visible emergency stop button, allowing immediate halting in case of operational anomalies or emergencies, ensuring the safety of personnel and preventing equipment damage.Q: How is production capacity and speed controlled on this device?

A: Production speed can reach up to 100 meters per minute and is easily adjusted via the PLC control panel. Operators can tailor settings to match process requirements, achieving up to 1500 kg/hr output while ensuring strip integrity.Q: What are the benefits of using a PLC-controlled rewinding solution?

A: PLC control enhances operational precision, reduces manual intervention, and allows for customizable automation. This results in higher efficiency, optimized workflow management, and consistent production quality for strip rewinding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Drawing Machine Accessories Category

Flyer for Wire Drawing Machines

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial Wire Drawing

Production Speed : Up to 1200 m/min

Function : Holding and guiding the wire during drawing process

Inlet Diameter : Customized as per requirement

Wire Spool

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Wire Drawing, Cable Manufacturing, Electrical Applications

Production Speed : Adjustable (depending on machine)

Function : Holding and winding drawn wire

Inlet Diameter : 10 mm 60 mm (customizable)

Wire Striper

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Wire Stripping and Insulation Removal

Production Speed : Variable (Manual)

Function : Stripping insulation from wires

Inlet Diameter : Up to 2 mm

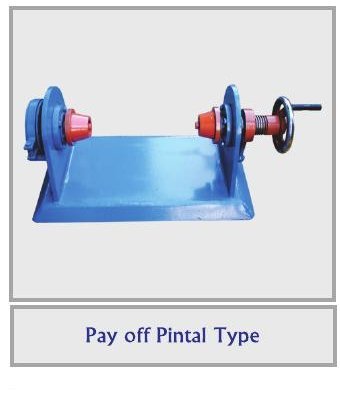

Pintal Pay Off Machine

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Wire Drawing Plant, Cable Manufacturing

Production Speed : Max 25 m/min

Function : Continuous Pay Off for Wire Drawing

Inlet Diameter : 1.5 mm to 10 mm

|

TOMER ENGINEERING WORKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry