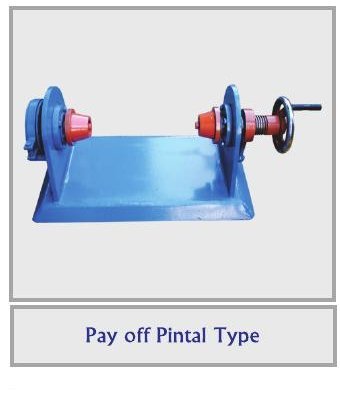

Pintal Pay Off Machine

Pintal Pay Off Machine Specification

- Inlet Diameter

- 1.5 mm to 10 mm

- Product Type

- Pintal Pay Off Machine

- Drawing Material

- Copper, Aluminium, Steel Wires

- Condition

- New

- Wire Material

- MS, SS, Aluminium, Copper

- Power

- 3 HP

- Function

- Continuous Pay Off for Wire Drawing

- Manufacturing Year

- 2024

- Drawing Passage

- Single

- Production Capacity

- Up to 1500 kg/hr

- Production Speed

- Max 25 m/min

- Max De-coiler Weight

- 2000 kg

- Application

- Wire Drawing Plant, Cable Manufacturing

- Voltage

- 440 V

- Structure

- Heavy Duty Steel Frame

- Coil Loading Method

- Manual Hydraulic Lift

- Safety Feature

- Electromagnetic Brake

- Pay Off Direction

- Vertical or Horizontal

- Suitable Wire Size

- 0.8 mm 8 mm

- De-coiler Type

- Floor Standing Rotational Type

- Floor Space Required

- 1.5 m x 1.5 m

- Control

- VFD Controlled Speed

- Operation Mode

- Automatic/Semi-Automatic

- Noise Level

- 75 dB

- Finishing

- Powder Coated

Pintal Pay Off Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 24 Pieces Per Month

- Delivery Time

- 4 Week

About Pintal Pay Off Machine

Features of Pintal Pay Off Machine :

- Rugged structure

- High operational fluency

- Application specific design

- Low maintenance

Designed for Versatility and Durability

The Pintal Pay Off Machine is engineered for continuous operation, supporting copper, aluminium, steel, and stainless steel wires. Its powder-coated heavy-duty steel frame ensures corrosion resistance and long-lasting performance, making it a dependable choice for high-output wire drawing and cable manufacturing facilities.

Advanced Control and Safety Features

Equipped with a Variable Frequency Drive (VFD), this machine offers precise speed control for both automatic and semi-automatic operations. The electromagnetic brake enhances operator safety, while the manual hydraulic coil loading system simplifies material handling during setup.

Optimized for Space and Efficiency

Occupying just 1.5 m x 1.5 m floor space, the Pintal Pay Off Machine efficiently handles large coil weights up to 2000 kg. Its de-coiler works in both vertical and horizontal directions at a low noise level (75 dB), ensuring effective integration into modern industrial environments.

FAQs of Pintal Pay Off Machine:

Q: How is the coil loaded onto the Pintal Pay Off Machine?

A: The coil is manually loaded using a hydraulic lift mechanism, allowing for secure and efficient placement of coils up to 2000 kg in weight.Q: What types of wire materials can the machine handle?

A: This pay off machine is suitable for mild steel (MS), stainless steel (SS), copper, and aluminium wires, supporting a wide range of wire drawing and cable manufacturing needs.Q: When should I use the automatic mode on this pay off machine?

A: Automatic mode is ideal for operations requiring consistent, uninterrupted wire pay off at controlled speeds, enhancing productivity in continuous manufacturing settings.Q: Where is the Pintal Pay Off Machine typically installed?

A: It is commonly installed in wire drawing plants and cable manufacturing facilities throughout India, fitting easily within a 1.5 m x 1.5 m floor area.Q: What safety measures are incorporated in the machine?

A: The electromagnetic brake provides an effective safety feature by rapidly stopping the de-coiler in emergency situations, reducing risks to operators.Q: How does the VFD-controlled speed benefit the production process?

A: VFD control enables precise adjustment of pay-off speed, accommodating various wire sizes (0.8 mm8 mm) and ensuring smooth feeding for optimal drawing through the single passage.Q: What are the main benefits of using this pay off machine in wire drawing plants?

A: Key benefits include high production capacity (up to 1500 kg/hr), compatibility with a range of wire materials, space efficiency, reduced noise, and consistent wire pay off for smoother downstream processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Drawing Machine Accessories Category

D-Scale Machine

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Inlet Diameter : 5 mm

Product Type : DScale Machine

Drawing Material : Mild Steel

Flyer for Wire Drawing Machines

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Inlet Diameter : Customized as per requirement

Product Type : Flyer for Wire Drawing Machines

Drawing Material : Mild Steel, Copper, Aluminum

Wire Spool

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Inlet Diameter : 10 mm 60 mm (customizable)

Product Type : Wire Spool

Drawing Material : Steel, Copper, Aluminum

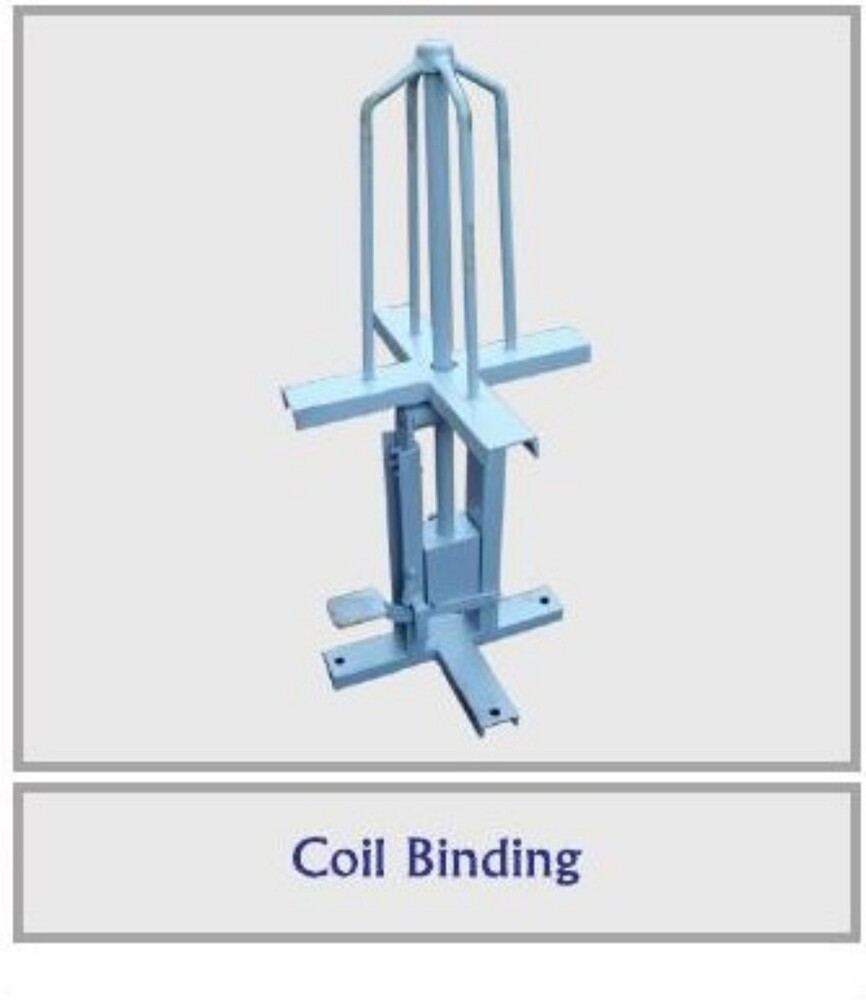

Coil Binding Machine

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Inlet Diameter : Up to 14 inches

Product Type : Coil Binding Machine

Drawing Material : Metal Coil

|

TOMER ENGINEERING WORKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry